Questions to ask before hiring cnc milling services near me

The Function of CNC Machining Providers in Modern Manufacturing and Engineering Solutions

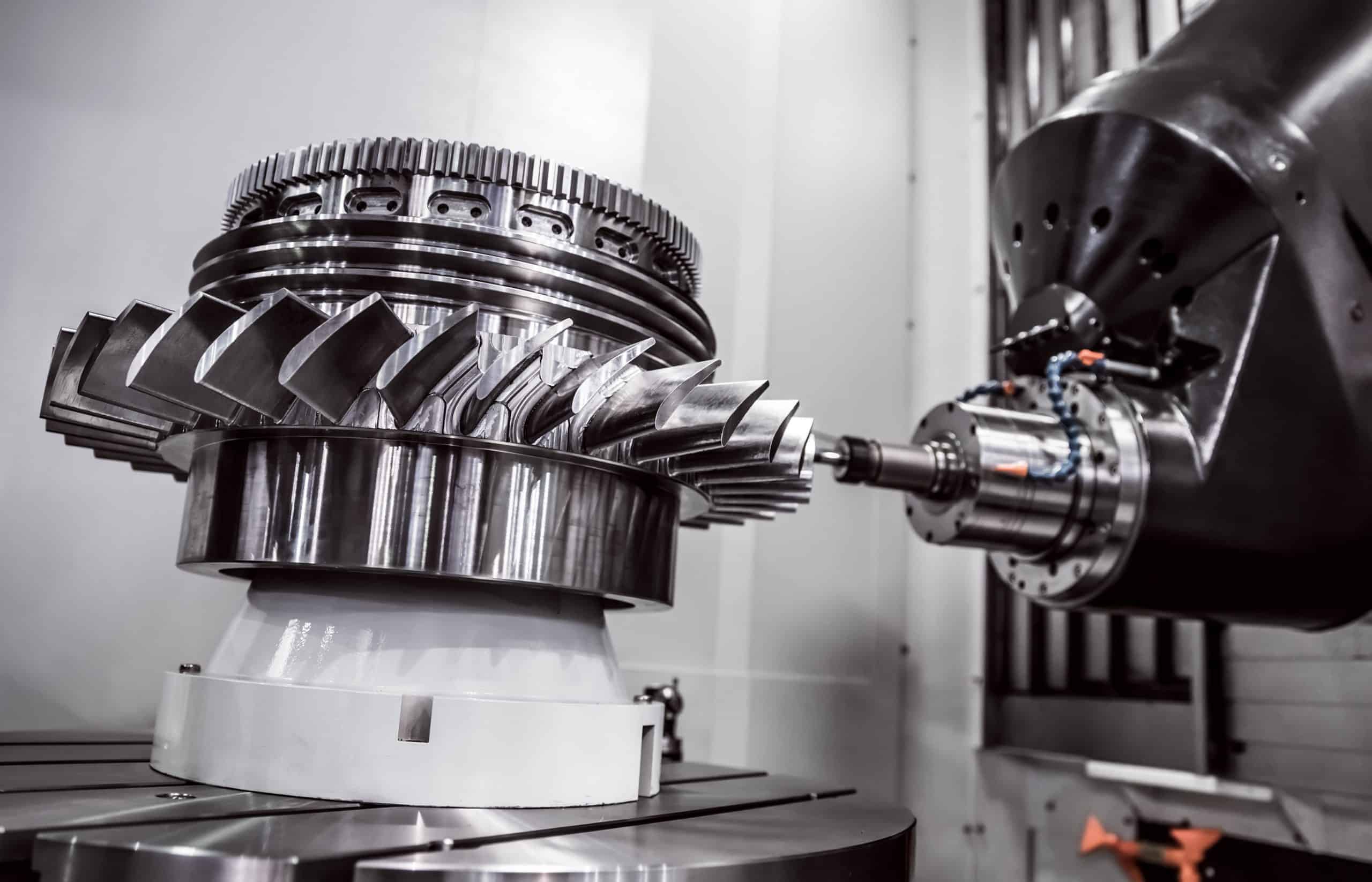

CNC machining solutions have actually become vital in modern-day production and engineering. They give accuracy and efficiency, making it possible for the production of facility parts with very little human oversight. This development not only minimizes manufacturing time and expenses however likewise attends to the raising needs of numerous markets. As modern technology develops, the landscape of CNC machining is established to change further - cnc milling services near me. The effects of these developments warrant closer exam

Comprehending CNC Machining: An Overview

CNC machining, a keystone of contemporary manufacturing, entails using computer-controlled devices to exactly cut and shape products. This modern technology integrates innovative software application and machinery to automate the manufacturing process, making certain high precision and effectiveness. CNC, which means Computer system Numerical Control, enables operators to input in-depth requirements that assist the device in implementing complex styles.

Different materials, consisting of wood, steel, and plastic, can be machined, making CNC flexible throughout different markets. The procedure starts with a digital design, generally produced making use of CAD software application, which is equated right into machine language for execution.

CNC machining includes numerous strategies, such as milling, turning, and drilling, each fit for certain applications. The fostering of CNC technology has transformed production abilities, making it possible for suppliers to produce elaborate components with very little human treatment. Consequently, it has actually come to be a crucial component in industries ranging from aerospace to vehicle.

Benefits of CNC Machining in Manufacturing

CNC machining supplies significant benefits in manufacturing, specifically when it come to accuracy and precision, which enhances product top quality. Additionally, it is cost-efficient, permitting reduced manufacturing prices while keeping high criteria. Its convenience in handling numerous products additionally highlights its value in modern production procedures.

Precision and Accuracy

In contemporary manufacturing, precision and accuracy are critical, and advanced machining strategies play a crucial duty in accomplishing these goals. CNC machining services give unmatched consistency in production, permitting makers to produce complex components with precise specifications. By making use of computer system numerical control, these machines remove human error, ensuring that each part meets rigorous resistances. The repeatability of CNC machining enables businesses to create large amounts of similar items without giving up high quality. Moreover, progressed software program utilized in CNC procedures enables intricate styles and quick modifications, boosting versatility in the production process. Eventually, the accuracy and accuracy used by CNC machining greatly contribute to enhanced item reliability and efficiency, cultivating development and fulfilling the ever-evolving demands of different markets.

Cost-Effectiveness

Cost-effectiveness stands out as a considerable benefit of CNC machining in the manufacturing field. By automating the machining process, firms can reduce labor expenses and reduce human error, which causes better efficiency. CNC machines operate continuously and can generate parts at a quicker price than traditional methods, ultimately reducing production expenses. Furthermore, the accuracy used by CNC machining lowers product waste, making certain that sources are made use of effectively. Therefore, businesses can achieve higher profit margins while maintaining high-quality criteria. The capability to create complex designs with marginal arrangement time additional improves expense efficiency. Overall, CNC machining presents an engaging remedy for suppliers looking for to enhance their operations and remain affordable in a requiring market.

Adaptability in Materials

Versatility in products is a characteristic of modern-day CNC machining, enabling manufacturers to deal with a vast variety important, including metals, plastics, timber, and compounds. This capability enables the manufacturing of varied elements tailored to details application demands. For instance, light weight aluminum and stainless-steel can be machined for durable industrial components, while plastics are optimal for corrosion-resistant and light-weight applications. Wood machining deals with the furniture and attractive sectors, while composites offer strength-to-weight benefits in aerospace and auto markets. The ability to switch over between products without significant reconfiguration improves workflow effectiveness and reduces preparations. Inevitably, this versatility encourages manufacturers to introduce and meet progressing market needs, solidifying CNC machining's role as a foundation of modern engineering services.

Key Industries Benefiting From CNC Machining Providers

CNC machining services play an essential role in various key sectors, particularly aerospace and protection, as well as auto element manufacturing. These markets depend on the precision and performance of CNC technology to satisfy rigid top quality and security requirements. The ability to generate complicated get rid of tight resistances settings CNC machining as an indispensable device in contemporary production.

Aerospace and Defense Applications

In the high-stakes domain name of aerospace and accuracy, protection and integrity are extremely important, making CNC machining services indispensable. These solutions allow the manufacturing of detailed components with exacting resistances, important for airplane, satellites, and army tools. CNC machining helps with the development of light-weight yet durable components, often utilizing sophisticated products such as titanium and carbon fiber. The capability to rapidly prototype and manufacture parts accelerates the development cycle, making certain that crucial systems are both reliable and reliable. Moreover, CNC innovation improves repeatability, minimizing the risk of human mistake and ensuring consistent quality throughout large production runs. As the aerospace and protection fields increasingly take on automation, CNC machining solutions will remain to play an essential role in meeting strict operational demands and governing requirements.

Automotive Element Manufacturing

The automotive industry, much like aerospace and protection, depends heavily on accuracy engineering to fulfill the demands of contemporary production. CNC machining services play a crucial duty in generating high-quality auto components, such as engine components, transmission real estates, and custom installations. These services allow manufacturers to accomplish limited tolerances and complex geometries, essential for enhancing car performance and safety. The capacity to rapidly adapt styles and generate models through CNC machining increases innovation within the industry. In addition, the scalability of CNC machining enables both little batch manufacturing and massive production, dealing with diverse market requirements. As self-governing and electric lorries gain traction, the reliance on CNC machining is poised to expand, even more strengthening its significance in automobile part manufacturing.

The CNC Machining Process: From Design to Production

Changing an electronic layout right into a concrete product entails a collection of precise action in the CNC machining process. At first, engineers use computer-aided style (CAD) software program to produce a thorough digital version of the desired element. This model is then transformed right into a layout suitable with CNC makers, usually through computer-aided manufacturing (CAMERA) software. The CNC device interprets this information to direct its operations.

As soon as the design is prepared, the chosen material is secured in the CNC equipment. The machining process starts, entailing various methods such as milling, transforming, and boring, where devices remove material to form the part according to specs. Throughout manufacturing, the machine continuously keeps track of and changes for precision, guaranteeing the final product meets the style criteria.

After machining, parts undertake completing procedures such as sanding or covering to enhance capability and visual appeals. This organized strategy assurances that premium parts are produced successfully and properly.

Innovations and Fads in CNC Machining Innovation

As improvements in modern technology continue to shape the manufacturing landscape, CNC machining is seeing significant developments that boost effectiveness and accuracy. One popular fad is the integration of fabricated knowledge and artificial intelligence, enabling flexible machining processes that website link enhance device courses and lower cycle times. In addition, the fostering of innovative materials, such as composites and light-weight alloys, increases the capabilities of CNC equipments, permitting the manufacturing of complicated geometries with higher strength-to-weight basics proportions.

Additionally, cloud computing and IoT (Internet of Points) innovations help with real-time tracking and data analysis, causing anticipating maintenance and reducing downtime. Automation via robotics is also becoming increasingly common, simplifying workflows and enhancing security in manufacturing atmospheres. The increase of 5-axis machining offers unequaled flexibility and precision, enabling the production of intricate components in a single setup. These developments collectively place CNC machining at the center of modern-day production remedies.

Future Expectation: The Evolving Role of CNC Machining in Design Solutions

CNC machining is poised to play a significantly vital role in engineering remedies as industries accept advanced technologies and advancing market demands. As automation and wise manufacturing gain grip, CNC machining services are expected to incorporate with Web of Things (IoT) devices and artificial intelligence (AI) to boost accuracy and performance. This assimilation will allow for real-time tracking and predictive upkeep, reducing downtime and enhancing production efficiency.

Furthermore, the surge of tailored production will necessitate more versatile CNC systems efficient in adapting to little set production with rapid turnaround times. Sustainability worries will additionally drive technologies in CNC machining, prompting the advancement of eco-friendly materials and procedures.

Inevitably, CNC machining will continue to progress, resolving the complexities of contemporary engineering challenges while giving cost-efficient and scalable options that meet the diverse needs of markets varying from aerospace to medical care.

Frequently Asked Concerns

What Materials Can CNC Machining Deal With?

CNC machining can function with a selection of products, including steels like steel, aluminum, and titanium, in addition to plastics such as acrylic and nylon. In addition, timber and compounds are also suitable for CNC machining processes.

How Do I Choose a CNC Machining Solution copyright?

When selecting a CNC machining company, one ought to consider their experience, tools quality, product abilities, customer testimonials, turnaround times, and prices. A thorough comparison assures the picked company fulfills certain project requirements successfully.

What Is the Regular Turnaround Time for CNC Machining Projects?

Typical turn-around times for CNC machining projects differ, usually ranging from a few days to numerous weeks, depending on job complexity, product schedule, and the solution supplier's workload. Timelines must be verified straight with the chosen company.

Exist Minimum Order Quantities for CNC Machining Services?

Just How Does CNC Machining Ensure Precision and Accuracy in Manufacturing?

CNC machining warranties accuracy and accuracy through computer-controlled operations, which minimize human mistake. Advanced software and top quality machinery help with exact dimensions, regular duplication, and detailed layouts, leading to exceptional components that satisfy rigorous specs and resistances.

CNC machining, a foundation of modern-day manufacturing, entails the use of computer-controlled devices to precisely reduce and form materials. CNC machining solutions provide unparalleled uniformity in manufacturing, enabling suppliers to create complicated components with precise requirements. CNC machining services play a necessary duty in different vital industries, especially aerospace and protection, as well as automotive element manufacturing. Additionally, the scalability of CNC machining enables for both tiny set production and massive production, providing to diverse market requirements. As automation and clever manufacturing go right here gain traction, CNC machining solutions are anticipated to incorporate with Internet of Things (IoT) gadgets and artificial intelligence (AI) to boost accuracy and efficiency.